ABOUT DIHUA

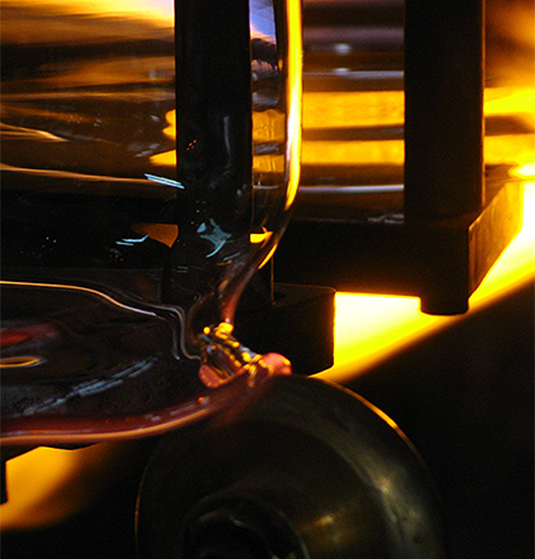

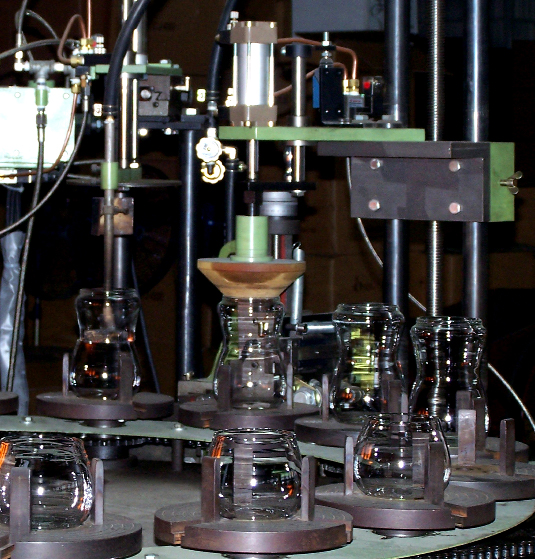

Jiande Dihua Decoration Co., Ltd specializes in heat-resistant glass manufacturing. The company is located on the bank of the beautiful Xinan River, which is only 30km from the worldwide famous sight of scenery---Qiandao Lake. The factory covers 6.7 hectares, with a building area of 55,925㎡, capital assets of 1.25 million USD, more than 70 units of production facilities, and over 200 staff, including 50 professional technicians. We have the world-class advanced total electrical glass melting kiln technique, and the country-wide leading technique in 3.3 boron silicon glass mechanized blowing production lines. We have applied automatic cutting and nipping techniques and accompanied supervising, measuring, and testing facilities, which would make our annual output reach 30 million pieces, enjoying an outstanding reputation both home and abroad. Due to the needs of business development, the company is newly equipped with 10 injection molding machines with highly precise automatic manipulators. The coffee pot electric kettle production line can undertake all kinds of coffee pots, electric kettles and other small household appliances assembly businesses. Welcome manufacturers from all over the world to negotiate! “Pursuing modern technology and perfecting our products” is the ideal of Dihua. In the latest competition environment, we insist on the business policy of "quality + services & demands + creation". With the development strategy of "creating the world-class brand", we would provide high-quality products and excellent services to our valued customers. For our mutual long-term and healthy development, Dihua would devote itself to building an international brand of China glassware.

In line with the corporate tenet of "Pursuing modern technology and perfecting our products", we regard quality as our life and create a glass industry with core competitiveness and core values.

Million

People

Sets

Acres

We get the drawings or samples from customers.

We will draw the 3D drawings according to the customers' 2D drawings or samples,and send the 3D drawings to customers for confirmation.

We will use the mold to make real samples and send them to customers for confirmation.

We will produce the products after getting the customers' confirmation and orders.

We will inspect the products by our inspectors or ask the customers to inspect together with us when finished.

We will ship the goods to the customer after the inspection result is qualified and confirmed by the customer.

Over the years, we have continuously adjusted and improved equipment and technology to make our products more perfect and serve every customer better.

We have our own testing lab and advanced and complete inspection equipment, which can ensure the quality.

We have a strong R&D team to develop and produce glass pots according to the drawings or samples.

We have both machine blown and man-made ,which can develop and produce kinds of pyrex glass with different shape.

We will make sample molds after getting the sample molds orders from the customers, which can be completed within 10 days.

Our annual production capacity can reach 30 million pieces to meet different customers with different purchase quantity.

We focus on developing high-quality heat-resistant glass for top-end markets.Our products are in line with international standard.